One of the things we love about straight razors is the ability to maintain them over many years with very few inputs. But, of course, the tradeoff is that you must maintain it to keep it shaving-sharp. Stropping the blade before and after each shave maximizes its performance, and oiling a carbon steel blade will keep it rust-free. When stropping alone no longer does the trick, it's time to break out the hones. For most end-users, we recommend the Norton 4k/8k hone, but only one that has been lapped. Read on to learn more about why we love the Norton hone, how we treat it to get the most out of it, and when to use it.

When to Hone Your Razor

It may be helpful to think of the razor's edge as an arrangement of microscopic metal fibers. A freshly honed and stropped blade will have uniform fibers aligned in the same direction such that they effortlessly glide through hydrated facial hair. However, hair is still pretty tough, so each pass distorts a few microscopic fibers. Not so many that you would notice, but enough that their accumulation would impact the quality of your shave. Stropping can realign them many times, but eventually, those metal fibers fatigue and break off and leave a dull spot. We call this normal wear and tear, and honing should only be required once or twice a year for a quality blade that is stropped regularly.

Now, imagine you never strop your razor. The fibers would deform further and further until no amount of stropping could realign them. The deformed edge must then be honed away to reveal fresh steel. Doing so would shorten the lifespan of the razor, but is necessary for restoring its usefulness. Similarly, waiting until the razor is so dull that it's impossible to shave with would require more steel removal than regular honing. For these reasons, we recommend stropping each time you shave and honing before it's desperately needed. This interval will change razor-to-razor and user-to-user, given the range of variables.

Choosing Razor Hones

Straight razors are not like the knives you might find in your pocket or kitchen; razor steels are harder and more brittle but also take a more refined, polished edge ideal for splitting hairs. It follows that razor hones will differ from those you'd use to sharpen your pocket knife. Razor hones will also be smoother and harder, producing the uniquely mirror-smooth razor's edge. For general maintenance, we recommend hones in the 1000-4000 grit range and 8000-12000 grit for finishing (higher numbers mean finer grits, in this case). It's important to note that most pocket knives and chef's knives (excluding authentic Japanese cutlery) will not benefit from sharpening on high-grit hones due to the treatment of their steels. Softer steels will perform better with microscopic serrations produced by grits under 1000.

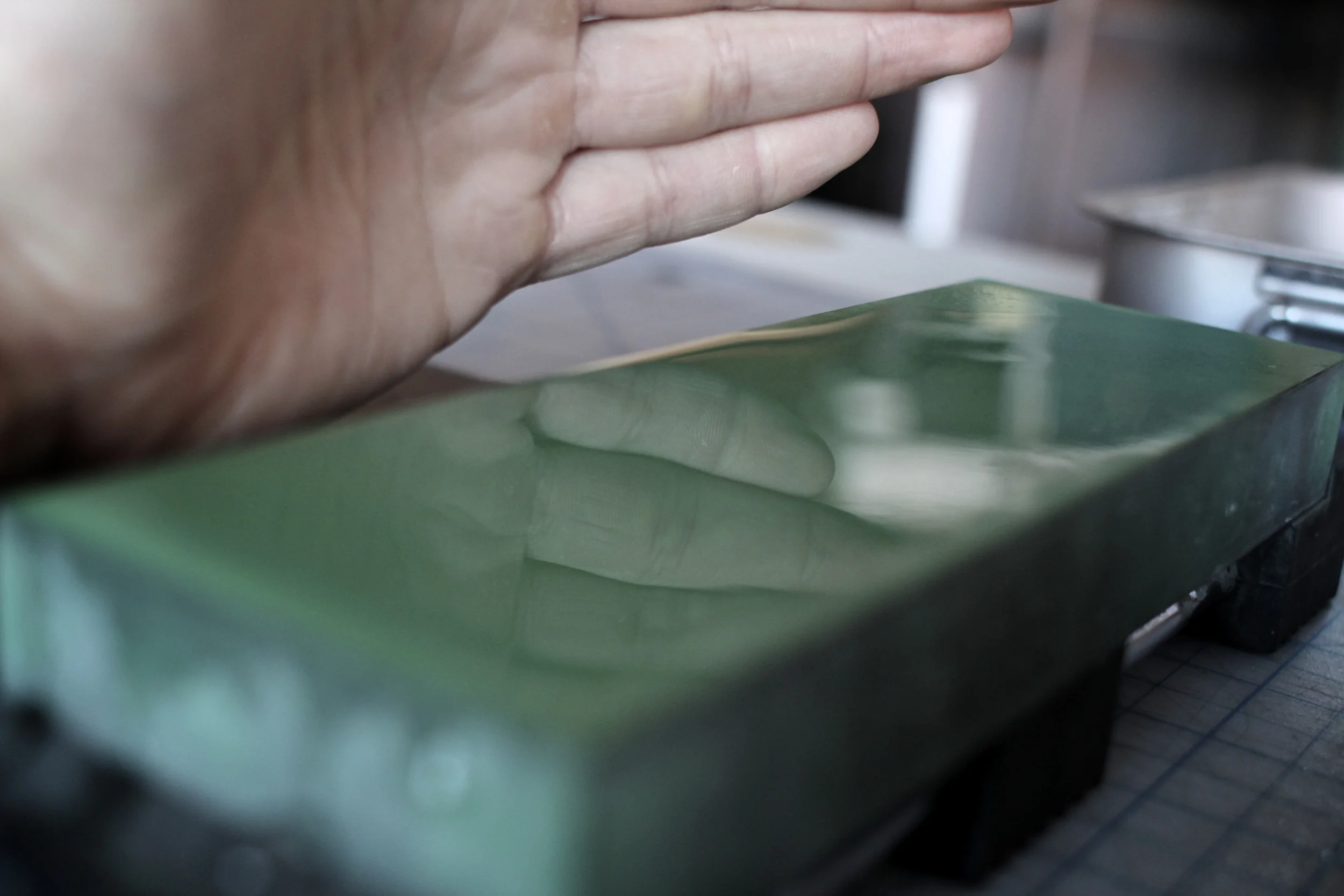

A razor hone that has been properly lapped has an surface finish that is immediately recognizable with the addition of water.

There are plenty of premium hone systems available, such as those by Naniwa or Shapton. We use a mix of Norton and Naniwa for our honing services. However, not everyone wants to spend $400 plus on what amount to sophisticated bricks. For this reason, we have narrowed our recommendation down to just one combination hone that meets the needs of most people honing their razors at home. It's affordable, versatile, and effective (after some minor adjustments in our workshop): the Norton 4k/8k combination waterstone.

The Norton 4k/8k Waterstone

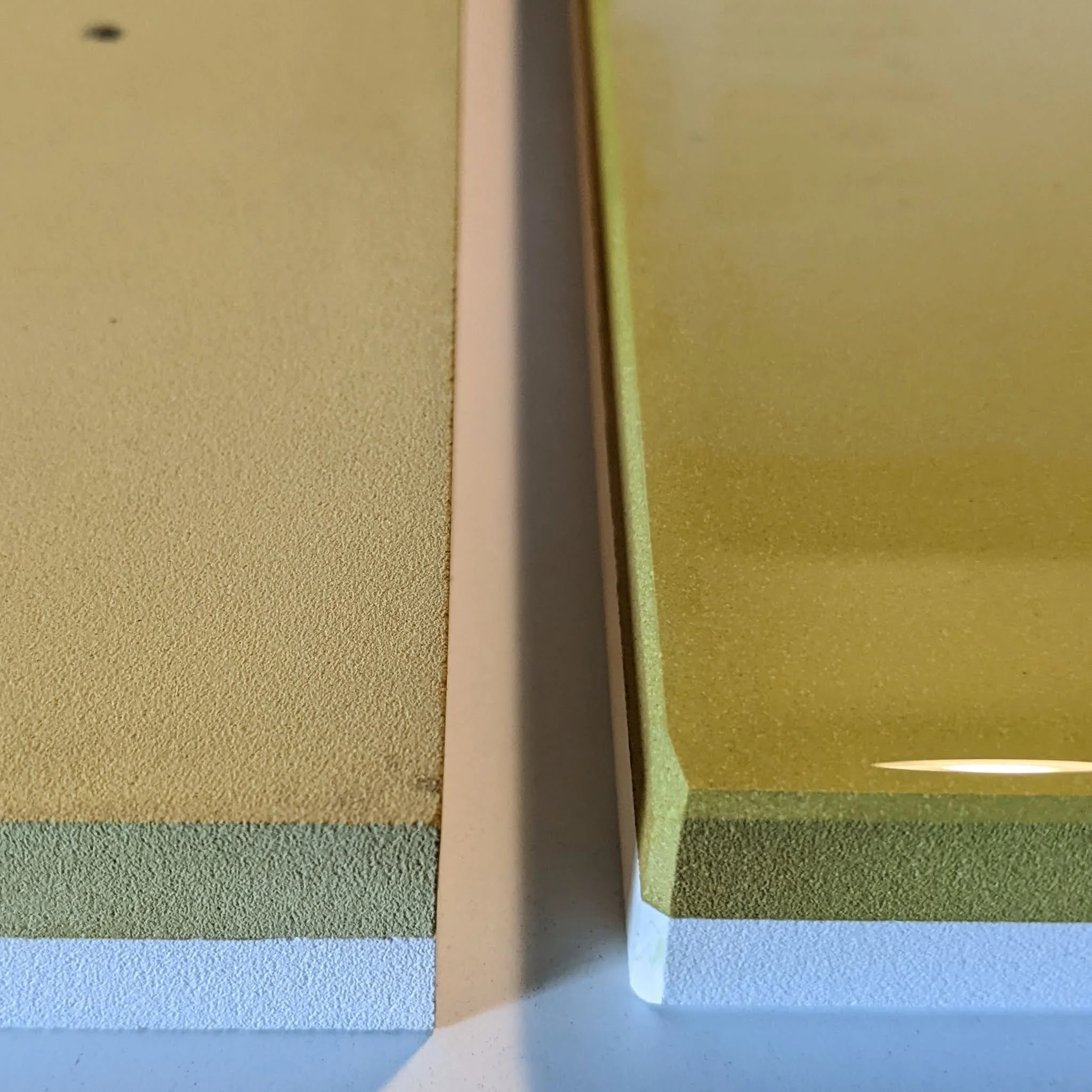

An unlapped (left) versus lapped (right) Norton 4k/8k combination waterstone

The Norton 4k/8k combination waterstone is our favorite general-purpose straight razor hone. The 4000-grit side is coarse enough to remove chips and dings efficiently, and the 8000-grit is sufficiently smooth to produce a mirror polish on the razor's edge suitable for shaving. Unfortunately, Norton leaves much to be desired in the surface treatment of their hones. Straight from the factory, they are unsuitable for honing straight razors. The honing surface must be lapped first to work well, which is why you can't purchase them just anywhere (and why our prices are a little higher than those you'll find elsewhere online). Lapping is the process of using a specialized plate that is perfectly flat and hardened to remove inconsistencies in the hone's sharpening surface. We use this to treat each hone before shipping, guaranteeing that the surface is uniform and optimal for honing your straight razors. We also bevel the edges of the hone to prevent chips and breakage. The result is a versatile hone that will last thousands of honing sessions!